JV330-160/130 Roll to Roll Eco-solvent Inkjet Printer

Add Time:2023-02-13 14:44:17

Source:

Add Time:2023-02-13 14:44:17

"330 Series" is a flagship model that combines Mimaki Engineering's technological expertise accumulated over more than 20 years to deliver beautiful image quality, high productivity, and high value added functions that assist in saving work.

"JV330 Series" is a mid- to high-end eco-solvent inkjet printer that has been added to the line-up to meet customer needs in addition to the entry-level 100 Series and standard 300 Series, 300 Plus Series.

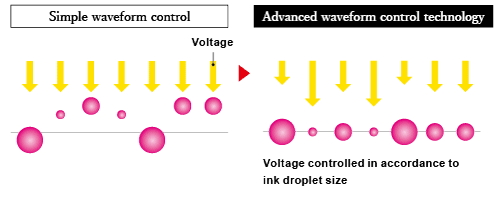

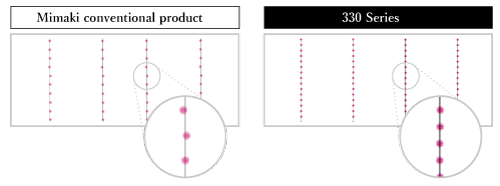

The 330 Series further enhanced the chassis rigidity upon overall review of the hardware design from ground up, also improving the accuracy of droplet placement up to 650%* in comparison to our conventional product through innovative waveform control technology. And also features a new drop technology to suppress banding, meeting the professional requirements of our customers to achieve overwhelming high image quality and high productivity.

* In comparison to our conventional product: Based on in-house e valuation of X-droplet placement accuracy ; results are not guaranteed.

Realizing high graphics with high image quality and definition

Adaptable to work requiring quick delivery by a high printing speed

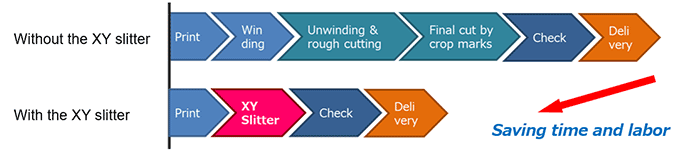

XY slitter capable of reducing post-process work by X-axis & Y-axis sheet-fed cut

Evolution of Usability: Media Changer, V-shape cut function, New maintenance mechanism

New conveyance mechanism ensures reliable long hour print operation

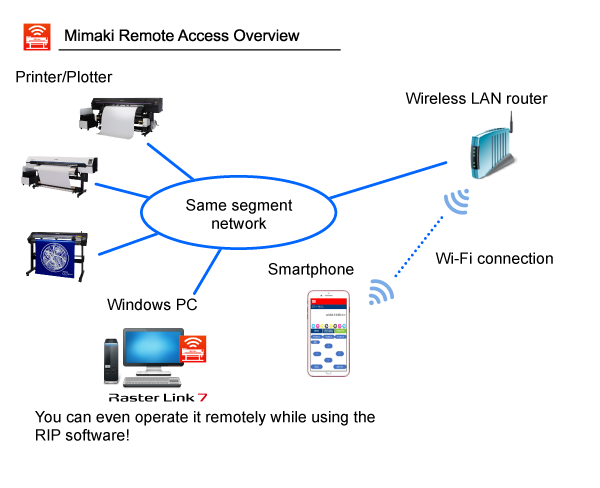

Mimaki Remote Access (MRA) enables wireless printer operations

Outdoor signboard Banner

Poster Illumination signboard

Rigidity of the chassis has been increased to approximately 230% of our conventional product to improve the levelness of platen (ejection surface)

Difficult-to-control ink droplets with a minimum size of 3pl are dispensed accurately through the evolution of waveform control technology

The highly accurate drop placement of the 330 Series achieves overwhelmingly high image quality without graininess.

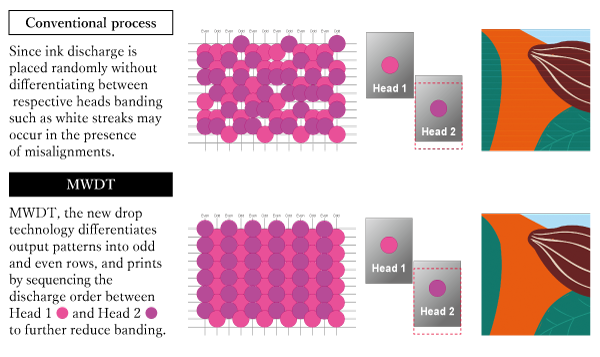

"Mimaki Weaving Dot Technology (MWDT)" is a revolutionary technology that achieves high image quality within the high productivity of the staggered head arrangement, making the banding caused by slight stagger adjustment errors and individual head differences less noticeable.

Example: Magenta solid color printing

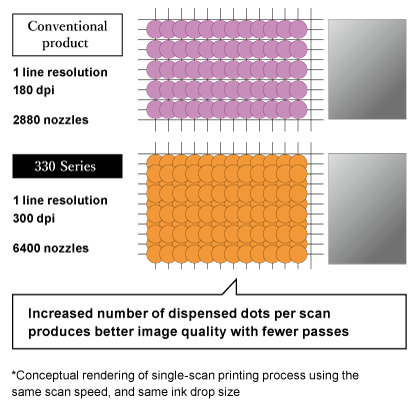

Improved single-line resolution and increased number of nozzles results in higher density of dots per pass, allowing for better image quality even in low-pass printing.

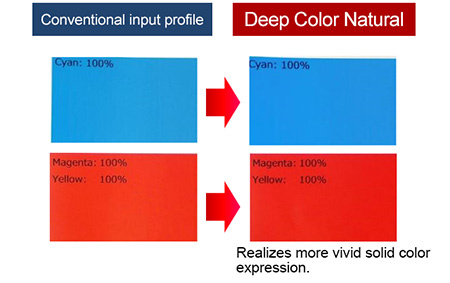

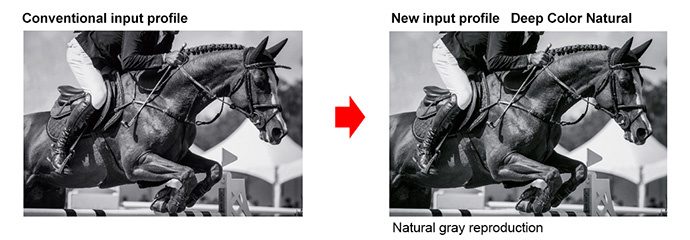

"Deep Color Natural" is a new input profile that is pursuit for the ease of use to sign graphics industry.

It realizes the high reproducibility of colors in indoor-outdoor sign graphics, such as eye-catching and vivid solid colors, natural and smooth skin colors, deep red, and neutral gray.

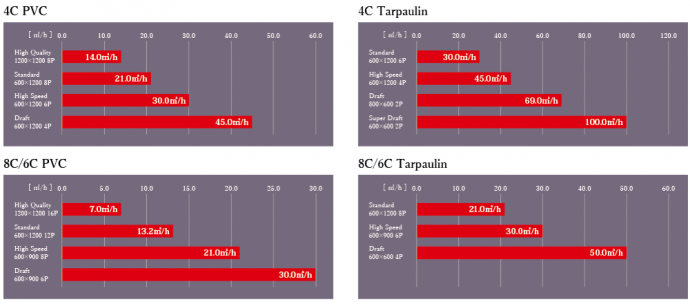

The high productivity of 21.0m²/h in the case of the standard mode using 4 colors and 13.2m²/h in the case of the standard mode using 8 colors are suitable to accomplish print job requiring quick delivery.

When outputting a 900 x 1800 mm sign (of PVC) using a high-speed mode of 30.0m²/h by 4 colors, the output of about 10 sheets/h is possible.

The highly precise cutting technology realizes in-line X-axis & Y-axis sheet-fed cutting.

The working space for post-print slitting becomes unnecessary for space-saving and enables efficient cut work and accommodates work requiring quick delivery to expand the range of your work.

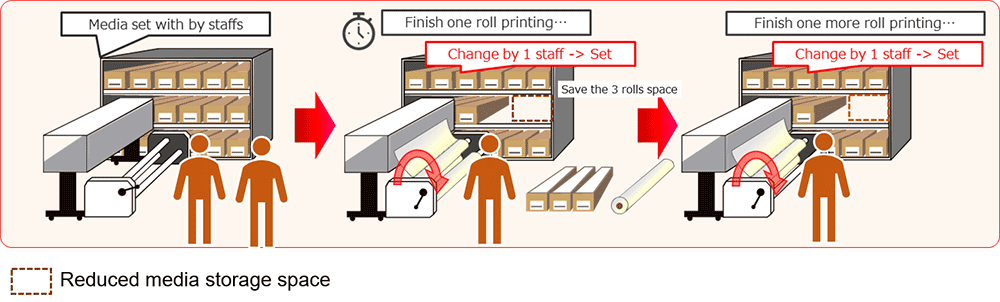

Setting three rolls of media at a maximum significantly saves labor for media replacement. Multiple media are attachable, and this creates a space-saving and efficient work environment.

Just lightly rotating a handle replaces the media, so anybody can use it easily.

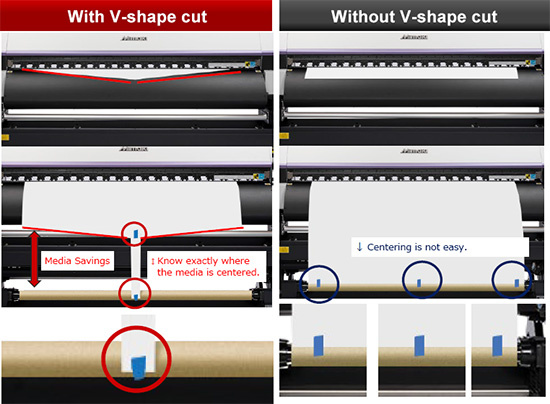

By cutting the media into a V-shape with the new "V-shape cut function", a single point can be enough to tape the media when winding it around the paper core. The center of media can be accurately attached to the paper core to reduce human error and avoid media conveyance misalignment.

It can also save material by using a small part of the media and taping at one point.

At the touch of a button of printer, it is to be chosen between two methods: "V-shaped cut" or conventional cut.

The new maintenance mechanism applies a cloth wiper that increases the removal rate of unwanted ink droplets from the nozzle surface. Compared with conventional scraping rubber wipers, the new wiping system soaks up unwanted ink droplets, reducing ink splattering on the head station.

By reducing the frequency of maintenance around the head and cap, daily care becomes simple and the machine can always be maintained in optimal condition.

Easy daily maintenance and cleaning of nozzle surfaces

The drive motor of the take-up unit is attached to both the left and right sides, which distributes the load on the paper tube and improves the take-up accuracy. Winding accuracy is improved.

The take-up power has been improved and the mechanism has evolved to be less prone to meandering.

Enables you to check the status of your machine remotely from a smartphone or PC. This allows you to operate the unit and the panel from a distance, making the work more efficient.

*1 Cut shape can be V-shaped cut or straight cut. Some of the samples in this website are artificial renderings. Specifications, design and dimensions stated in this website may be subject to change without notice (for technical improvements, etc). The corporate names and merchandise names written on this website are the trademark or registered trademark of the respective corporations. Inkjet printers print using extremely fine dots, so colors may very slightly vary after replacement of the printing heads. Also note that if using multiple printer units, colors could vary slightly from one unit to other unit due to slight individual differences.Specifications

JV330-130 JV330-160 Print head On-demand piezo head (2 staggered layout) Print resolution 600dpi, 800dpi, 900dpi, 1200dpi Print gap By manual 3 levels (2.0/2.5/3.0 mm) Ink Type/Color Eco-solvent ink

SS21 (C, M, Y, K, Lc, Lm, Lk, Or, W)

BS4 (C, M, Y, K)Capacity SS21: 2L ink pack (500ml ink pack only for White ink)

BS4: 2L ink packInk circulation Circulation in damper MCTv2 Maximum print width 1,360mm (53.5") 1,610mm (63.4") Media Maximum width 1,370mm (53.9") 1,620mm (63.8") Thickness 1 mm or lower Roll diameter φ250 mm or less Mountable no. Max. Three rolls Roll weight One roll:Max. 45 kg (99.2 lb) or less

Three rolls:Total 90 kg (198.4 lb) or lessRoll inside diameter 2 inch / 3 inch Media cutting Auto cutting by cutter of head unit *1 Interface Ethernet 1000 BASE-T (Recommended) / USB2.0 Hi-speed Certifications VCCI class A, FCC class A, ETL IEC 62368-1,

CE Marking (EMC, Low voltage, Machinery directive, and RoHS),

CB, REACH, Energy Star, RCM, EAC, KC, UKCAPower supply Main unit:(Single phase AC100-120/200-240V±10%, 50/60Hz±1Hz) ×2 Power consumption Max. 1,440 W or less x 2 / Min. 4.5 W or less (Sleep mode) Operational environment Temperature: 20–30 °C (68–86 °F)

Humidity: 35–65% Rh (Non condensing)

Recommended temperature: 20–25 °C (68–77 °F)

Dust level: General office levelDimensions (W×D×H) 2,920 × 1,215 × 1,305 mm

(115.0 x 47.8 x 51.4")3,170 × 1,215 × 1,305 mm

(124.8 x 47.8 x 51.4")Weight 358 kg (789.2 lb) 368 kg (811.3 lb) Ink set

SS21

[C,M,Y,K,Lc,Lm,Lk,Or,W]C M Y K C M Y K Lc Lm Lk Or C M Y K Lc Lm W BS4

[C,M,Y,K]C M Y K

| JV330-130 | Maximum print width: 1,360 mm (53.5") |

|---|---|

| JV330-160 | Maximum print width: 1,610 mm (63.4") |

地 址:Add:(Hong Kong)—Unit 1B, 17/F Kwong Sang Hong Centre, No. 151-153 Hoi Bun Road, Kwun Tong, Kowloon, Hong Kong. (Vietnam)—Room 520, 5th Floor, Thanh Dat 3 Building, No. 4 Le Thanh Tong, May To Ward,Ngo Quyen District, Hai Phong City, Vietnam. (China) —No.101-103,1st Floor 4th Block,DongQiao Intelligence Valley Industrial Park,No.21 Xinyuan South Road,Li Xin Dong Cheng District,Dongguan City,Guangdong Province,China.

邮政编码:

电 话:Tel: China +86 0769 22307900 / HongKong +852 3622 5561

传 真:Fax: China +86 0769 22307900 / HongKong +852 8148 2386

手机:MP: 13827250130

邮 箱:Email: enquiry@solardigital.net

投诉邮 箱:Complaint email: enquiry@solardigital.net