JFX200-1213 EX UV Inkjet Printer

Add Time:2024-12-18 14:32:17

Source:

Add Time:2024-12-18 14:32:17

Security Code:CMSEASYOMhfs5qTXWM1LCG572

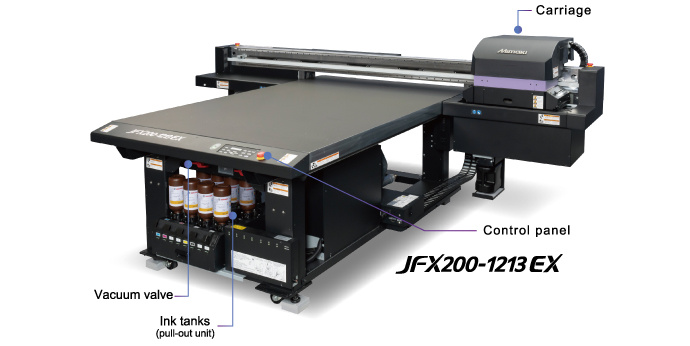

The "JFX200-1213 EX" is a middle-size flatbed UV printer with about half the print size of the "JFX200-2513 EX," which has been well received worldwide for its high image quality, high added value, and high production prints.

This printer is ideal for upgrading from a desktop UV printer or as an entry-level digital printing machine.

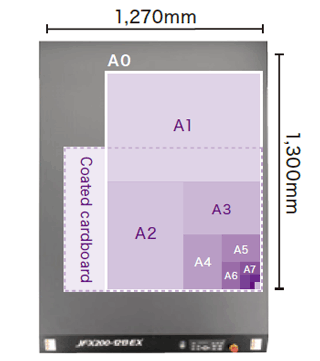

Middle-size flatbed (up to 1270 mm × 1300 mm)

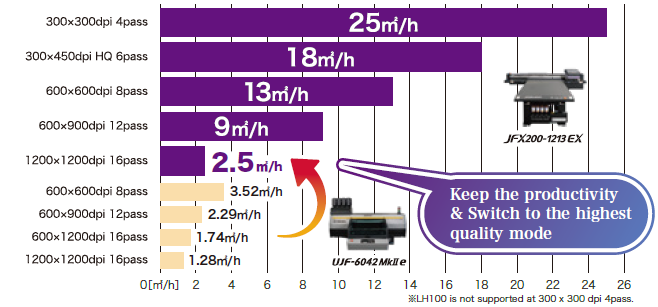

Max. 25m²/h The highest-in-class productivity

Even faster texture printing

High image quality printing

Operator-friendly user interfaces easily accessible from the front

Mimaki's technology for realizing stable operation

|  |  |  | |||

| 3D lenticular | Nameplate (Full-color) | Nameplate (Etching) | Card | |||

|  |  |  | |||

| Key chain | Novelty | Flip wallet smartphone case | Paper package | |||

|  |  |  | |||

| Switch | Photo album | Wedding board | Water bottle | |||

Sign graphics use: supports A0 size sign panel

Paper and package: supports standard coated cardboard size

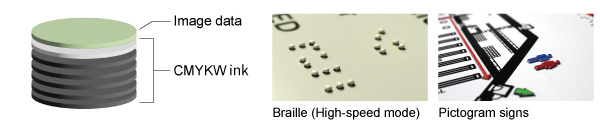

Increased braille printing speed. 2 types expression capability for application requirement.

All of these can be done just with standard design software and RasterLink7.

Bring texture design into shape instantly.

Braille part is constructed by clear ink emboss printing. Transparent braille dots don't interrupt the based graphic design.

High-speed texture printing by bi-directional printing, utilized for braille and pictograms.

Automatically generates texture layering data based on graphic data in RasterLink7.

Layers UV ink to make bumpy expressions, the thicker the layers are, highlights bumpes and dips.

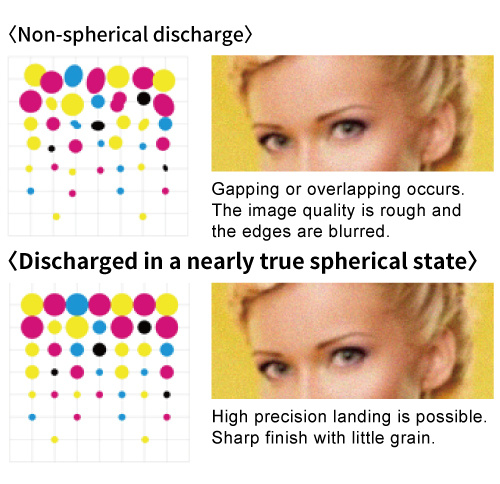

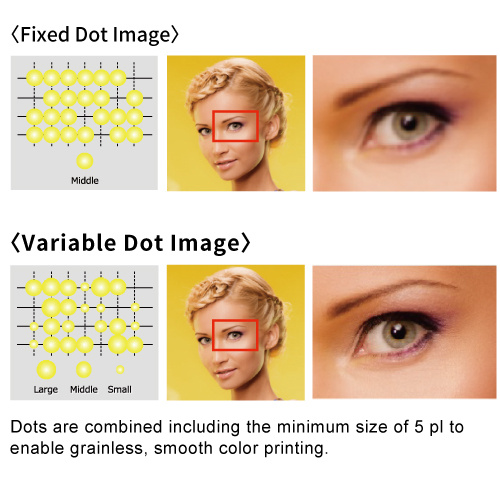

By discharging spherical ink droplets directly, depositing of droplets is facilitated and overlapping between dots is reduced, achieving a sharp print quality with low grain.

Three different ink dot sizes are used in printing to enable high-quality prints with reduced graininess.

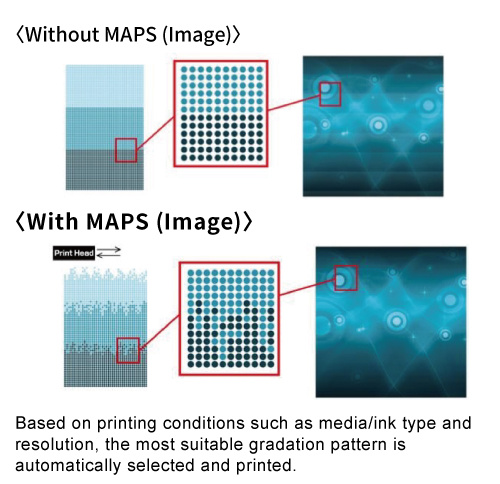

Banding (horizontal stripes), uneven color, or glossy streak can be reduced to produce smooth prints by printing pass boundaries fading in gradation.

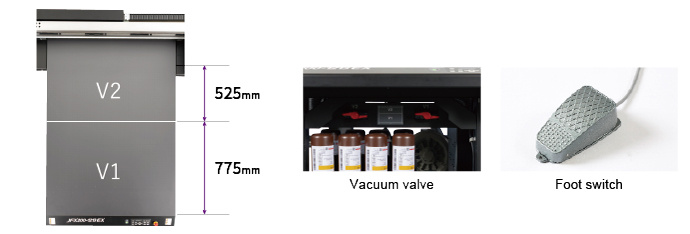

The vacuum area is divided into a front section and a rear section. The valve can be used to switch between them easily depending on the media size. The foot switch allows you to turn vacuum on/off while checking the media location.

The ink bottles can be accessed from the front side of the printer for replacement and maintenance. This minimizes the pathway to be followed by operators, increasing work efficiency.

墨囊组件(取出之后)

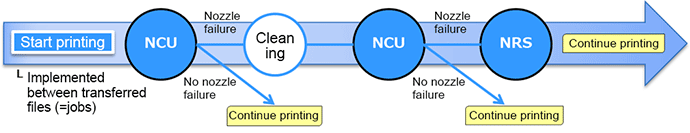

NCU (Nozzle Check Unit) detects the status of nozzles automatically. When the NCU detects a missing nozzle, it automatically performs cleaning. If cleaning does not solve the problem, NRS (Nozzle Recovery System) automatically replaces the defective nozzles with other nozzles, which enables users to continue their operation without waiting for service representative.

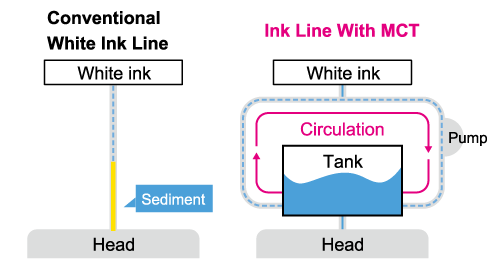

MCT is used in the ink tank and channel. The white ink is circulated at regular intervals to prevent pigment sedimentation that leads to malfunctions of the printhead.

| JFX200-1213 EX | Maximum print area: 1,270 x 1,300 mm (50.0 x 51.2") |

|---|

| JFX200-1213 EX | ||

|---|---|---|

| Head | On-demand Piezo head (Array of 3 heads stagger) | |

| Print resolution | 300, 450, 600, 900, 1,200dpi | |

| Ink | Type | UV curable ink : LUS-120 (C, M, Y, K, W, Cl) |

| UV curable ink : LUS-150 (C, M, Y, K, Lc, Lm, W) | ||

| UV curable ink : LUS-211 (C, M, Y, K, W, Cl) *Only available in some regions. | ||

| UV curable ink : LUS-350 (C, M, Y, K, W, Cl) | ||

| UV curable ink : LH-100 (C, M, Y, K, Lc, Lm, W, Cl) | ||

| Primer: PR-200 *1 | ||

| Ink Supply system | 1liter bottle, 250ml bottle (LH-100, LUS-120, PR-200 only) *2 | |

| Ink circulation system *3 | White ink circulation using Mimaki Circulation Technology (MCT) | |

| Maximum diagram dimensions (W×D) | 1,270×1,300 mm (50.0×51.2") | |

| Media | Dimensions (W×D) | 1,270×1,300 mm (50.0×51.2") |

| Height | Max. 50 mm (2.0") | |

| Weight | Less than 50 kg/m2 (110.2 lb./ft2), non concentrated load | |

| Media absorption | Blower adsorption type + foot switch | |

| Number of absorption area partitions | 2 partitions (X-axis direction) | |

| Curing device | LED-UV system | |

| Interface | USB2.0, Ethernet | |

| Safety standard | VCCI class A, CE mark, CB report, U.S. safety standard UL (UL62368-1), RoHS Directive, FCC Class A, Machinery directive, RCM | |

| Input power supply | Single phase, AC 200-240 V, 50/60 Hz, less than 12 A | |

| Power consumption | Less than 2.88 kVA | |

| Installation environment | Temperature | 15 – 30 °C (59 – 86 °F) |

| Relative humidity | 35 – 65 %Rh | |

| Accuracy maintained temperature | 20 – 25 °C (68 – 77 °F) | |

| Temperature gradient | Less than ± 10 °C/h (± 18 °F/h) | |

| Dust | Similar to standard office environments | |

| Assembled Dimensions (W×D×H) | 3,142×2,320×1,235 mm (123.7×91.3×48.6") | |

| Weight | 510 kg (1,124.3 lbs.) | |

*1 PR-200 is not compatible to use with LUS-211 and LUS-350.

*2 Only 1 liter bottle is available when the initial ink filling.

*3 MCT works only with white ink.

・Inks would not be cured when printing speed is faster than that of draft mode.

Some of the screens and printing samples in this website are artificial renderings.

Specifications are subject to change without notice.

All trademarks or registered trademarks are the property of their respective owners.

Inkjet printers print using extremely fine dots, thus colors may vary slightly following replacement of the printing heads. Also note that if using multiple printer units, colors may vary slightly among the units due to slight individual differences among the units.

Inks and substrates:

Please note that properties and adhesion, weather resistance etc. of ink and substrates can vary. Therefore please test materials before printing.

Some substrates require primer before printing. Please test materials beforehand or ask your sales representative.

Safety notice:

You are dealing with UV light sources that may harm your health. Please follow below guidelines strictly:

Do not look directly into the UV light source nor place your hand, or expose your skin directly to the UV light source.

Depending upon print mode, there might occur some VOC emittance from printed parts not yet cured and hardened.

In addition, please read the instructions and guidelines of the manual carefully and follow those.

地 址:Add:(Hong Kong)—Unit 1B, 17/F Kwong Sang Hong Centre, No. 151-153 Hoi Bun Road, Kwun Tong, Kowloon, Hong Kong. (Vietnam)—Room 520, 5th Floor, Thanh Dat 3 Building, No. 4 Le Thanh Tong, May To Ward,Ngo Quyen District, Hai Phong City, Vietnam. (China) —No.101-103,1st Floor 4th Block,DongQiao Intelligence Valley Industrial Park,No.21 Xinyuan South Road,Li Xin Dong Cheng District,Dongguan City,Guangdong Province,China.

邮政编码:

电 话:Tel: China +86 0769 22307900 / HongKong +852 3622 5561

传 真:Fax: China +86 0769 22307900 / HongKong +852 8148 2386

手机:MP: 13827250130

邮 箱:Email: enquiry@solardigital.net

投诉邮 箱:Complaint email: enquiry@solardigital.net